Process Industries

Process industries are generally engaged in performing physical and chemical changes on materials. In order to build the desired properties, performance characteristics and economics into the finished products, processes must be controlled. Important to this control are the properties of the raw materials, the characteristics of the unit processes and operations, residence time under specified, temperatures, pressures, and concentrations, and the methods of measurement employed.

In addition to the conventional quality problems faced by process industries, they experience some unique ones quite different to those of batch mode manufacturing. First, the measurement methods may in themselves be miniature chemical, physical, or biological processes requiring control.

Next, testing time may be relatively long compared with batch reaction time . This may require control decisions to be anticipated. Also, product specifications may not fully define performance under widely varying customer conditions.

As in the case of most industries, the process industries share problems of rapid product obsolescence and the need for prompt conversion of research effort into profitable production. In particular, the quality needs of the marketplace change rapidly and, often, unpredictably. To illustrate, concern with ecology and consumer safety may require development of different fuels and lubricants for automobile engines; flame-retardant paints and textiles; biodegradable detergents, fertilizers, and insecticides.

Since some of its end products, in particular drugs and food, are directly consumed, the process industries have become further involved in how products from one sector (eg, fertilizers, pesticides) influence the composition and properties of products in another sector (food, drugs). Further, the ability to measure minute quantities has raised questions about the effect of pesticide residues accumulating in fish and drinking water from surface water runoff of fertilized fields.

Last, human response to materials, either in process or as finished goods, varies widely both in its intended usage or in accidental exposure. This necessitates extensive toxicity studies and clinical trials which are time consuming, expensive, and frequently complex. Statistically designed experiments are the order of the day.

Traditionally, responsibility for achieving quality controls has been concentrated in three broad areas:

- The research and development laboratory

- The analytical or control laboratory

- The manufacturing plant

But, what is control?

We define quality control as a managerial process during which we:

- Evaluate actual performance

- Compare actual performance to goals

- Take action on the differences.

The concept of control is one of “holding the status quo” keeping a planned process in its planned state so that it remains able to meet the operating goals.

Unfortunately, a process that is designed to be able to meet operating goals does not stay that way. All sorts of events can intervene to damage the ability of the process to meet goals. The main purpose of control is to minimize this damage, either by prompt action to restore the status quo, or better yet, by preventing the damage from happening in the first place.

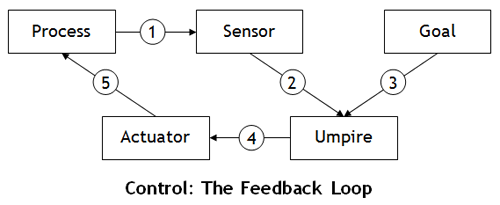

The control process takes place by use of the feedback loop. It addresses sporadic problems.

- The sensor evaluates actual performance

- The sensor reports performance to an umpire

- This umpire also receives information on what the goal or standard is

- The umpire compares actual performance to the goal. If the difference warrants action, the umpire energizes an actuator

- The actuator makes the changes needed to bring performance in line with the goals.

What is improvement?

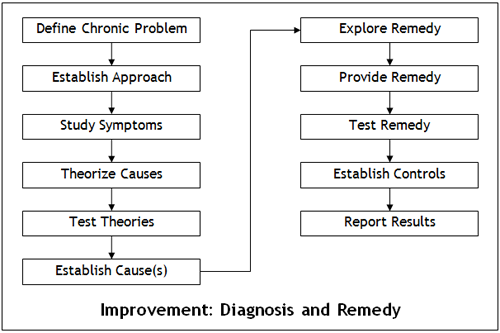

Improvement means the organized creation of beneficial change; the attainment of unprecedented levels of performance. This involves recognizing and eliminating chronic problems.

Quality improvement is needed for two dimensions of quality: product features and freedom from deficiencies. To maintain and increase sales income, companies must continually evolve new product features and new processes to produce those features. Customer needs are a moving target. To keep costs competitive, companies must continually reduce the level of product and process deficiencies. Competitive costs are also a moving target.

Much of the conventional approach to quality improvement is directly applicable to the process industries. However, the tools for analysis often must be quite sensitive, since many industry products are high-volume, low-profit (commodity) materials. In such cases, large sums of money rest on small differences in yield. The tools of analysis needed to deal with such small differences must be flexible enough to accommodate numerous variables, many of which are nonlinear, and which may interact with other variables. Such tools do exist, and the industry has made such progress in applying them to improve yields and controls.

CREDITS: Suresh Lulla, Founder & Mentor, Qimpro Consultants Pvt. Ltd.