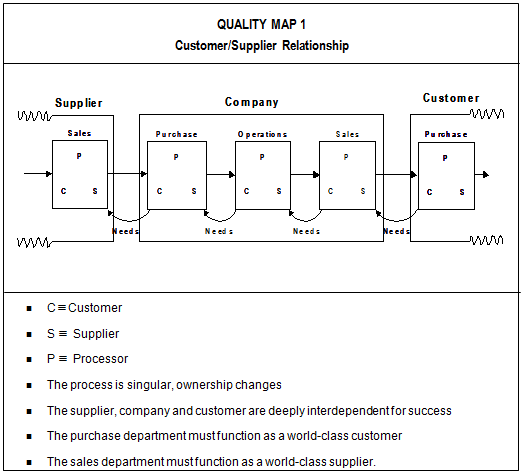

A supplier/customer relationship is forged whenever a business purchases goods or services from another and each time a person asks another to undertake an activity. A process is any activity, which takes an input and transforms it into an output. The supplier is anyone who generates an output from a process, while a customer is anyone, within the company or outside, who receives the output of the process from the supplier. All activities within a business are often made up of a series of complex supplier/customer chains. As shown in Quality Map 1, each department (and person) is a customer of the previous process in the chain, and a supplier to the next process. If activities are to be carried out right the first time, it is essential that customer needs for each process within the chain are identified and met.

External customers are the ones who pay your bills. Businesses continue to survive only because of their ability to meet the needs of their external customers.

Internal customers: Each transaction in a large business is the result of a number of internal supplier/customer relationships. The sales team concludes the sale; it specifies the characteristics required to the production team; the delivery team arranges for the product to be delivered; and the finance team renders the invoice for the transaction. Each of these teams relies on inputs from their colleagues to enable them to complete their process right the first time. It is only by satisfying the (internal) needs for each of these processes that the needs of the external customer can be met.

In the early 1990s - post-liberalization, several Indian companies changed character. Typically, over 50 per cent ownership shifted to the foreign collaborator and with that, the post of chief executive shifted from an Indian to a foreigner. I was invited by the new chief executive of a pharmaceutical company in south Bombay that had undergone this metamorphosis.

During my visit to the company, I had much to learn from this foreign chief executive. He had never visited India before. His earlier postings had been in Brazil, Indonesia and Kenya. His contract in India was defined for three years, or as he put it, 1000 days. His performance would be measured by the European head office, in terms of the degree of customer focus. The Indian organization’s ‘power structure’ and ‘status structure’ did not concern him.

On the first day of his appointment, the chief executive invited all first line executives to the board room. He asked them a few basic questions, and requested each executive to complete his own template:

- Who are my customers?

- What do I deliver to them?

- What are their needs?

- What is my current performance?

- What actions can I take to improve?

After much guided discussion, he impressed upon his executives the concept of the internal customer. The list of customers for each executive was now substantial. He further facilitated a Pareto analysis, executive by executive, and recommended an initial focus on the top five customers only.

As the next step, he asked each executive to articulate a proactive meeting schedule for each of the top five customers on a weekly basis. Each meeting was to be no longer than 15 minutes, with a one point agenda: “How can I improve my performance for you?” The customer’s stated needs were to be logged.

Each week, over the next two weeks, the chief executive audited the previous week’s meetings and the actions taken by the executive. At the time of our meeting, he was confident that a customer focused culture was in the making. He had crossed a key milestone in three weeks. His actions (walk) had done all the talk.

At Midland Bank in England, the internal-customer concept is well institutionalized. Internal departments consider the bank’s branches to be their customers. Each branch regularly rates the quality of service it receives from each department on a five point scale - with one as the top and five as the lowest rating. If an internal service provider receives a rating between four and five, he or she must actually visit on the branch to learn where the problems lie.

Perhaps the most important success factor in bringing the internal customer concept alive in any organization is the spirit with which it is implemented. In our organizational lives, most of us are conditioned to avoid meddling in other people’s business. We are often reluctant to point out a peer’s problems and certainly to make them visible to all in the form of an internal customer rating. And we are even more reticent if the supplier is someone above us in the hierarchy. The problem is that unless the facts and data of internal customer relationships are reported openly, the entire process will fail. Indeed, it might even increase waste as employees go through the motions of rating but do not tell the truth.

As a step towards achieving external customer delight, all companies should know the names of their principal external customers. Their purchase departments are likely to be the focal points for material, component and product purchases. But do we know who else within these businesses might assess our performance as a supplier? If the business is quality driven then their quality team might be monitoring the quality of the goods we supply to them, or the response times for service calls. If they are dissatisfied with our performance, they are likely to look for another supplier. Their goods inwards department may have needs like when and how the goods should be delivered. Their production department may have needs relating to interchangeability of items. Their finance department will have needs concerning the address and content of our invoice. Liaison with their marketing team might even yield an opportunity for the joint development of products to our mutual advantage. Each of these customers may influence the decision to purchase goods or services from us. It is important to understand the needs of all the groups within our customer’s organization that influence its purchasing decisions. Only then will we be able to satisfy their needs.

Meeting the external customer’s needs involves two major steps:

- Identify the external customer’s needs

- Ensure that the internal processes result in meeting the external customer’s needs at a minimum cost.

This can be accomplished by using the quality planning process - Quality Function Deployment (QFD). QFD is a planning process as opposed to a tool for problem solving or analysis. Customers’ wants and needs are the inputs to the matrix (refer Quality Map 2). The process cannot begin without these input interchangeabilities. QFD essentially forces an organization to get in touch with the people who use its products.

CREDITS: Suresh Lulla, Founder & Mentor, Qimpro Consultants Pvt. Ltd.