Introduction

In today’s competitive marketplace, a company’s ability to provide products and services that satisfy the needs of its customers is critical to its success. Quality standards are documents that define the contractual, functional, and technical requirements for all the activities that will ensure that a product, a process, a service or a system is fit for its intended purpose. But, with customer needs changing rapidly with time, can companies accept standards that are static? Certainly not. For companies to attain world class quality and increase their market share, they must challenge the standards by addressing the three interrelated, basic processes of managing for quality: quality planning, quality control and quality improvement. This interrelationship is called the Juran Trilogy.

Standards are important, and were developed to achieve amongst others, uniformity, intercommunication and interchangeability and should not be viewed as a guarantee for quality. This paper examines the various kinds of standards available to industry and provides a proven approach to move beyond standards by addressing the key processes of managing for quality.

History as a Standard

The most widely used standard is historical. We compare sales, shipments, accidents, scrap, etc., of a particular year with a year ago. The merit of using history as a standard is that it appeals to practical men. However, the historical standard can be fatally defective. There is the risk that poor performance may be perpetuated. Also, our preoccupation with history may blind us to our opportunities.

The Engineering Standard

The engineering standard is directed at what performance should be rather than at the historical level. It is widely used in shops, mainly for materials usage, quality, process yields and labour man-hours. The engineering standard is a composite of actual performance, seasoned with engineering judgement. However, as yet, there are no reliable ways to set standards for some of the most critical performances - share of market, level of morale, etc.

The Market Standard

The market standard is the performance of our competitors. The market standard is influential, if not decisive, in the prices we pay for wages, salaries, materials and services. It imposes limits on our selling prices, our product quality (setting the minimum acceptable level), our speed of delivery and much else. The market standard concept serves to sensitize us to the existence of a spectrum of performance.

ISO 9000 as a Standard

The ISO 9000 can be considered as the minimum market standard to do business in Europe after 1992. There are five standards in the ISO 9000 series. The first, ISO 9000, standard provides some basic definitions and concepts and summarizes how to select and use other standards in the series.

The ISO 9001, 9002 and 9003 standards are applicable for external quality assurance purposes for contractual situations. ISO 9001 is to be used to ensure conformance to specified requirements during design and development, production, installation and servicing. ISO 9002 is used when only production and installation conformance are to be ensured. ISO 9003 is the least detailed standard and requires only that conformance in final test and inspection be ensured.

ISO 9004 contains guidance on the technical, administrative and human factors affecting the quality of products and services. This standard is for internal use only and is not to be used in contractual situations. The standards list the essential elements that make up a quality system in some detail, starting with the responsibilities of management. Whole sections are devoted to each aspect of the quality system: marketing, design, procurement, production, measurement, post production, materials control, documentation, safety and the use of statistical methods. This standard could be used to evaluate a company’s progress towards a fully implemented quality system. This is where a company should begin their implementation of the ISO standard.

Exports

It is perceived that ISO 9000 accreditation will be a requirement to do business with Europe after 1992. However, it is not a requirement unless the buyer company emphasizes it. The wider acceptability of the ISO 9000 in Europe and other parts of the world will make registration to the ISO 9000 a compulsory requirement for exporting to these countries. But, supplier surveillance will not be eliminated because manufacturers have special requirements not specifically called for by a general application of the standards.

Benefits

There are several benefits of registration including:

- It is one standard that has almost universal acceptance

- Fewer, more focused supplier audits

- Easier, faster and more comprehensive learning

- Increased productivity and quality caused by better systems

- Sales in the European community

- A recognizable logo that can be added to sales literature

- Being listed with registered suppliers in a registry.

But there are certain shortcomings that companies need to be made aware of:

- These standards are generic. They represent the minimum requirements for an effective quality system to assure that the product will meet customer requirements. These standards define what must be in a quality system but do not tell a company how to document the quality system. What is a quality manual? What makes up an adequate quality plan? What makes up an adequate quality policy? These questions are not answered.

- These standards do not make a provision for continuous improvement. This is a serious drawback that, perhaps, will be addressed in the future. Until then, continuous improvement to lower costs, to improve product and service quality, and remain competitive in today’s world economy is still the responsibility of management.

- The ISO 9000 series requires no evidence of a satisfactory track record of performance eg. in product quality or delivery.

The Decreed Standard

The decreed standard is imposed on us in several ways: by government regulators; by the customer, who for reasons of his own must have a particular date, quality, package; or by top management who want a new design ready in time for the semi-annual trade show. The decree, at times has little evident relation to historical, engineered or market values.

Excellence as a Standard

Companies in the United States are mandating that their suppliers apply for the Malcolm Baldrige Award within a given time period if they are interested in building a long-term supplier relationship. Such mandating companies have already set the example by winning the award themselves and help their suppliers to achieve the same. It should be noted that application for the Malcolm Baldrige Award requires companies to go beyond the historical, engineering or market standards and move to better levels of performance. To achieve such a level of performance, companies must focus their attention to satisfy the needs of their customers, continuously improve their products and services in a dynamically changing environment, and improve their processes to be flexible and more responsive to changing customer needs. This would require companies to integrate The Juran Trilogy (refer exhibit 1) as a way of managerial life.

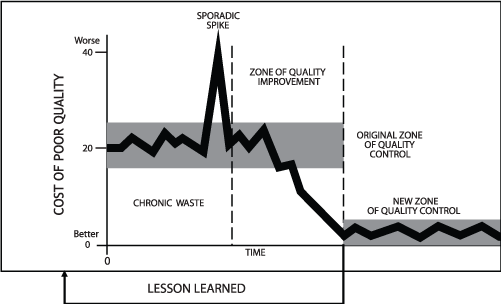

Exhibit 1: The Juran Trilogy Diagram

Quality Improvement

Improvement is the process of creating a breakthrough from the standard to a new better level of performance. Such breakthrough follows a systematic structured series of steps as developed by Dr J M Juran.

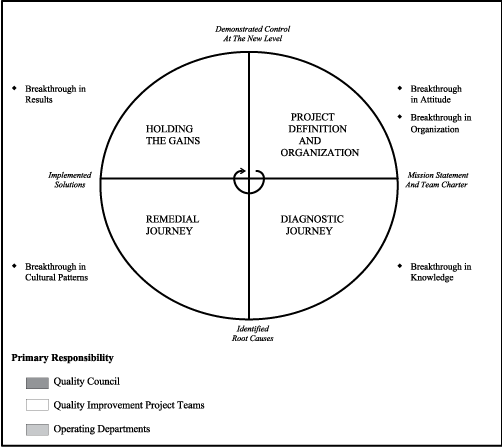

Experience has shown that such breakthroughs in performance require a series of contributing breakthroughs (refer exhibit 2). First, there must be a breakthrough in attitude. We must challenge the historical standard of performance and must prove to others that there is both a need and a way to do better.

Next, there often must be a breakthrough in organization. Typically, the reasons for poor performance lie across functions and departments within an organization. Historically, no one has been responsible for solving these cross-functional problems. Therefore, we must often create new organizational forms that are responsible for (1) identifying chronic problems and (2) solving those chronic problems. The recommended way to do this would be to form a high level Quality Council that consists of senior executives to provide leadership to this effort. As a start, projects can be selected based on the cost of poor quality and cross-functional managerial teams should be selected to solve these problems.

Achieving a new level of performance also requires a breakthrough in knowledge. We must reach new plateaus in our knowledge of how the process operates and what causes poor performance. But this new knowledge alone is often not sufficient to guarantee that a new level of performance will be attained. It should be noted that people work in the process and are accustomed to the historical level of performance. Hence, we must also achieve a breakthrough in cultural patterns. This involves such things as dealing with cultural resistance to change and providing training in the new methods. Finally, we must implement the new methods and verify a breakthrough in results. Quality improvement and substantial breakthroughs in performance will not occur unless all these contributing breakthroughs are achieved.

Exhibit 2: The Breakthrough Cycle

A few companies in India are using this approach to quality improvement and have seen success. The reduction in cost of poor quality in these companies is substantial and the savings have run into several lakhs of rupees per annum. There is considerable evidence to suggest that the cost of poor quality in any organization, in India, is around 20% of sales revenue. By implementing a quality improvement programme, companies are bound to improve quality and reduce such quality related costs. On the other hand, there is very little evidence to suggest that substantial reductions in cost can be achieved merely through ISO 9000.

Quality Planning

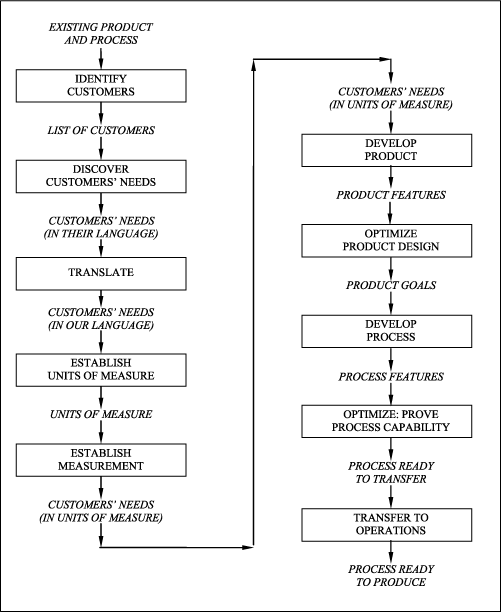

Even if an organization were to eliminate all deficiencies in its existing products, services and processes, does it guarantee customer satisfaction? Maybe, maybe not. It will depend on whether products and services are designed to meet customer needs. To get more customer-driven, companies need to adopt modern quality planning methods to plan their processes and products. This will require abandoning the traditional approach to quality planning. It will require companies to adopt a structured systematic approach to quality planning to benchmark and be Best-in-Class.

The structured systematic approach to Quality Planning is shown as exhibit 3.

Exhibit 3: The Quality Planning Roadmap

By the use of such an approach, customers would get what they want and not have to choose from what is available. It will lead to greater customer satisfaction and hence increased market share, making products more saleable worldwide.

Quality Control

Control, by definition, means staying on course, adhering to standards. Quality control is well understood by many managers. Indeed, some may think this is the only process by which we manage for quality. We must change this thinking.

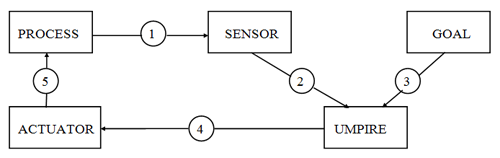

The key elements of quality control in the simplest form are:

- A sensor for evaluating the actual performance

- A collator to compare this actual performance with the intended or standard performance

- An effector to take corrective action on the difference.

And the process repeats from the first step. A typical control loop is presented as exhibit 4.

Exhibit 4: The Control Feedback Loop

Control is an important process and it helps:

- Preventing adverse changes from occurring in the process

- Maintaining the level of performance achieved at the end of planning

- Maintaining a new level of performance once a breakthrough has been achieved.

Conclusion

Although standards such as the ISO 9000 lay a sound foundation for a total quality system, as a stand alone they are not enough. In fact, hardly adequate. To achieve quality leadership requires that companies be customer driven and make a habit of annual improvements. Companies that wish to lead the quality race must set upon themselves stretch goals, such as, to reduce the cost of poor quality by 50 per cent and simultaneously be certified as Best-in-Class by over 50 per cent of its customers by 1992.

CREDITS: Suresh Lulla, Founder & Mentor, Qimpro Consultants Pvt. Ltd.