Carbon black manufacture guarantees a carpet of carbon in the plant. Yet, at Thai Carbon Black I was told by the Plant Manager, “You can eat from the floor”. And he was right.

Cement manufacture belches air pollution. Yet, at Vikram Cement the Plant Manager introduced me to a beautiful rose garden enveloping the plant. Wow.

Both plants belong to the Aditya Birla Group. One in Bangkok, and the other in Khor, Madhya Pradesh. Both plants have adopted 5S principles.

Conclusion: Structured housekeeping practices do not need a visa.

A structured approach to housekeeping was first adopted in Japan in the 1950s. The purpose of this initiative was to build a Quality Culture, organization by organization. The translated version of this approach is referred to as 5S.

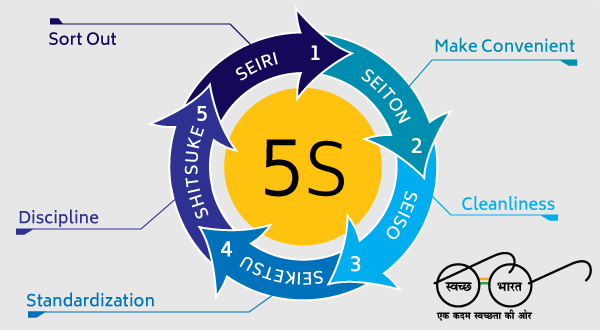

The 5S principles are:

S1: Seiri – Sort Out

S2: Seiton – Make Convenient

S3: Seiso – Cleanliness

S4: Seiketsu – Standardization

S5: Shitsuke – Discipline.

For a Swachh Bharat, we need an aggressive adoption of 5S. The underlying 5S principles are easy to communicate in any language. They also lend themselves to visual communication.

Further, 5S principles can be easily understood by employees at all levels in governmental and private organizations / institutions. In my view, 5S principles must also be taught to school children.

Caution: Sincere exhortations by leaders, as well as poster campaigns, will simply not deliver the goal of a Swachh Bharat. Leaders need to invest time to review implementation, at a reasonable frequency.

The Japanese use the Deming Plan-Do-Check-Act mantra, for adopting any management system. Plan and Check (Review) are upper management responsibilities. On the other hand, Do and Act are delegable.

The surprise by-product of effective 5S implementation is a reduction in Cost Of Poor Quality (COPQ). The cost reduction gains go straight to the bottom-line making our respective organizations more competitive.

I know numerous quality professionals who would be pleased, and anxious, to make 5S happen in India.

Are you interested?

CREDITS: Suresh Lulla, Founder and Mentor, Qimpro Consultants Pvt. Ltd.